To strengthen small manufacturing for the defense industry

Surging the DIB at Scale

Emerging technologies, such as additive manufacturing; artificial intelligence (AI); automation and robotics; industrial internet of things (IIoT); quantum computing; and virtual and augmented reality (XR), hold tremendous potential to remake the American manufacturing base. However, fulfilling the potential of these technologies requires collaboration with key stakeholders; policy research; and workforce development.

The Knudsen Institute was founded on the idea that technology and policy must be developed in an integrated fashion. That will enable a truly resilient domestic manufacturing industrial base capable of meeting surge requirements.

Research Areas

Select Current Projects

The Evergreen Data Asset on the DIB

The Knudsen Institute realizes that data on the DIB is an essential ingredient to surge. To this end, we are supporting the development of SADE: the Semi-autonomous Data Engine. SADE continuously harvest data from a variety of sources creating a real-time understanding of the DIB. At Knudsen, we utilize SADE to understand not only the OIB and current supply chains, but alternative sources of supply, workforce data, and technology developments. Our goal is not only to identify all possible manufacturing capabilities to meet surge demands but the entire potential ecosystem for the DIB to tap into.

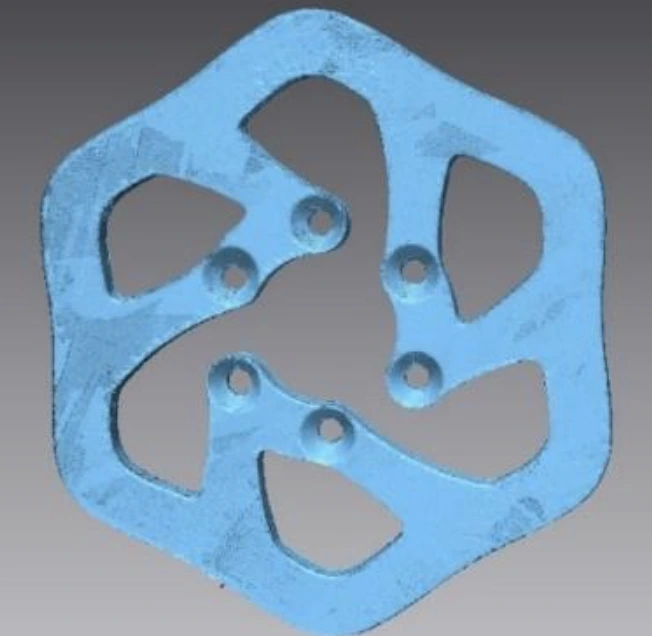

Deep Learning Model Development: generating CAD from Scans

A key blocker to surge is the lack of quality technical data or TDPs for parts. This is just not a legacy platform sustainment problem; this issue occurs on newer platforms being built today. While there has been progress to utilize scans to generate CAD files automatically, a lot of work is still needed to turn them into suitable CAD files. AI is a natural choice to tackle this problem, but the results from the top general LLM-based multi-modal models are less than desirable. We are focused on building custom Deep Learning models with an aim to build CAD with accuracies less than typical aerospace manufacturing tolerances.

Select Papers

Peer-reviewed papers from our affiliated researchers.

- Debnath, B., Pourfarash, Z., Raman, S., & Ghorpade, B. (2025). Integration of reverse engineering and finite element analysis for reconstruction and assessment of an off-road vehicle brake rotor. IISE Annual Conference Proceedings.

- Pourfarash, Z., Debnath, B., Ghorpade, B., & Raman, S. (2025). The impact of additive manufacturing on supply chain resilience in small and medium-sized enterprises: A literature survey. IISE Annual Conference Proceedings.

- Debnath, B., Pourfarash, Z., Ghorpade, B., & Raman, S. (2025). Integrating Reverse Engineering for Digital Model Reconstruction and Remanufacturing of Mechanical Components: A Systematic Review. Metrology, 5(4), 66.